Thread Rolling Screw Meaning . thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. the thread rolling process of screws involves deforming metal stock through the use of dies to create external threads along the surface. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. 3.9k views 3 years ago #stemeducation #fasteners. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it.

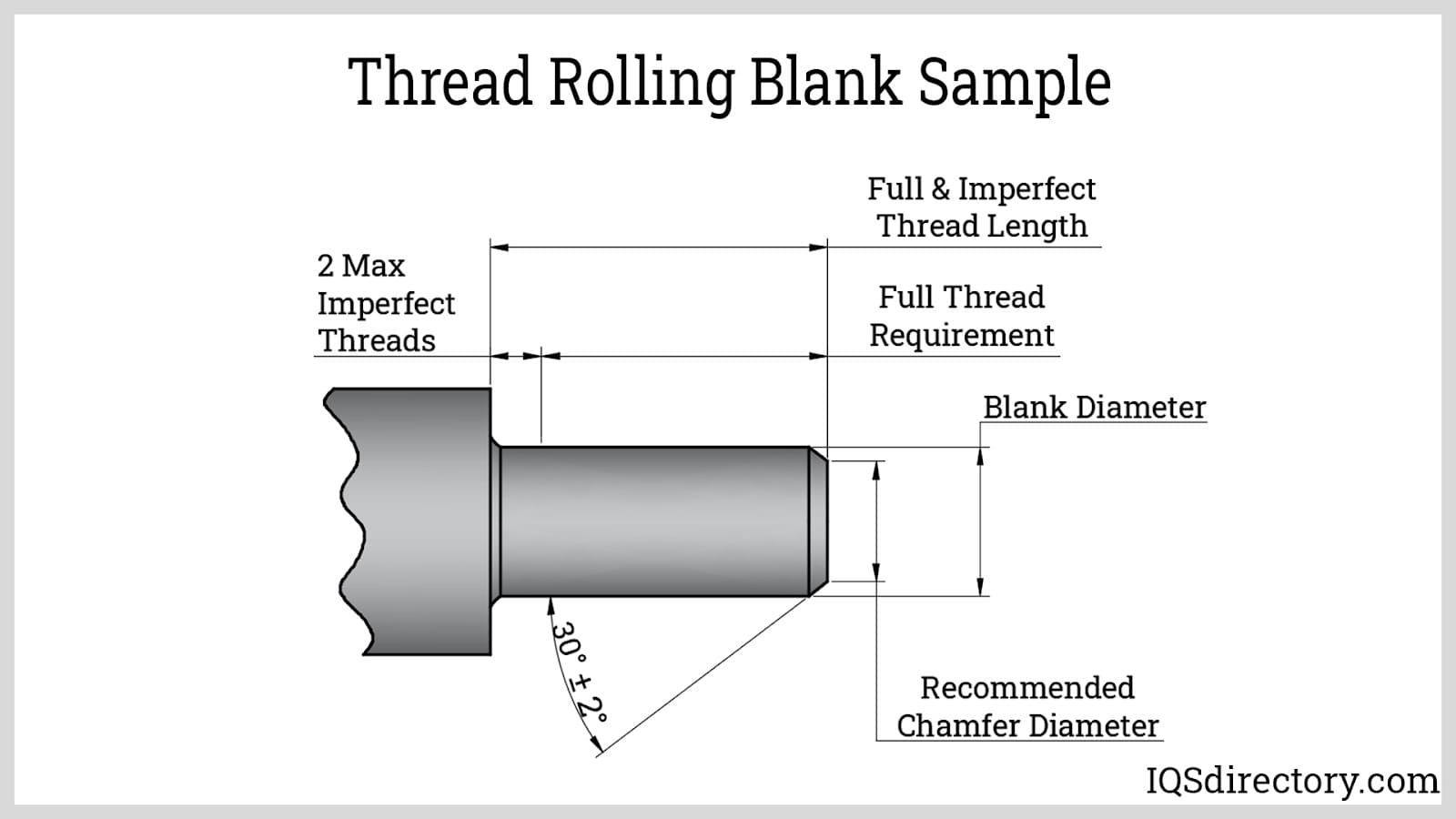

from www.iqsdirectory.com

thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. the thread rolling process of screws involves deforming metal stock through the use of dies to create external threads along the surface. 3.9k views 3 years ago #stemeducation #fasteners. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it.

Thread Rolling What Is It? How Does It Work? Process, Types

Thread Rolling Screw Meaning threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. 3.9k views 3 years ago #stemeducation #fasteners. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. the thread rolling process of screws involves deforming metal stock through the use of dies to create external threads along the surface. thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it.

From www.iqsdirectory.com

SelfDrilling Screw What Is It? How Does It Work? Types Of Thread Rolling Screw Meaning thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. the thread rolling process of screws involves deforming metal stock through the use. Thread Rolling Screw Meaning.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Meaning the thread rolling process of screws involves deforming metal stock through the use of dies to create external threads along the surface. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. thread rolling is a straightforward process that begins with cutting a metal bar to length and forging. Thread Rolling Screw Meaning.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Thread Rolling Screw Meaning instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. 3.9k views 3 years ago #stemeducation #fasteners. threads produced using a thread rolling machine are 30% stronger than. Thread Rolling Screw Meaning.

From www.iqsdirectory.com

Screw Machined Parts & Products What Are They? Types & Uses Thread Rolling Screw Meaning instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it.. Thread Rolling Screw Meaning.

From www.accu.co.uk

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Meaning 3.9k views 3 years ago #stemeducation #fasteners. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. the thread rolling process of screws involves deforming metal stock through. Thread Rolling Screw Meaning.

From gurukulonline.weebly.com

Screw Threads Terminology Gurukul Online Thread Rolling Screw Meaning thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. 3.9k views 3 years ago #stemeducation #fasteners. the thread rolling process of screws involves. Thread Rolling Screw Meaning.

From www.accu.co.uk

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Meaning 3.9k views 3 years ago #stemeducation #fasteners. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. threads produced using a thread rolling machine are 30% stronger than untreated cut. Thread Rolling Screw Meaning.

From www.accu.co.uk

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Meaning instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. 3.9k views 3 years ago #stemeducation #fasteners. threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. thread rolling is commonly used in the production. Thread Rolling Screw Meaning.

From www.zerofast.com

Thread Terminology zero products inc. Thread Rolling Screw Meaning thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as. Thread Rolling Screw Meaning.

From dxozapjfw.blob.core.windows.net

What Thread To Use For Threading at Willie Busch blog Thread Rolling Screw Meaning 3.9k views 3 years ago #stemeducation #fasteners. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. the thread rolling process of screws involves deforming metal stock through the. Thread Rolling Screw Meaning.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Meaning 3.9k views 3 years ago #stemeducation #fasteners. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. threads produced using a thread rolling machine are 30% stronger than untreated cut. Thread Rolling Screw Meaning.

From fastfixtechnology.com

Thread rolling screws or thread forming screws what's the difference Thread Rolling Screw Meaning threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. thread rolling is a straightforward process that begins with cutting a metal bar to length and. Thread Rolling Screw Meaning.

From www.accu.co.uk

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Meaning threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well. Thread Rolling Screw Meaning.

From www.accu.co.uk

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Meaning the thread rolling process of screws involves deforming metal stock through the use of dies to create external threads along the surface. threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. thread rolling screws are fasteners that create their own threads by displacing. Thread Rolling Screw Meaning.

From www.amazon.com

Steel Thread Rolling Screw for Metal, Zinc Plated, Hex Washer Head Thread Rolling Screw Meaning thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. 3.9k views 3 years ago #stemeducation #fasteners. the thread rolling process of screws. Thread Rolling Screw Meaning.

From toolnotes.com

Thread Specifications ToolNotes Thread Rolling Screw Meaning thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. instead of removing material to create threads, thread rolling redistributes the material of the workpiece to form the threads. thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create. Thread Rolling Screw Meaning.

From www.accu.co.uk

Buy M6 x 12mm T30 Torx Countersunk Thread Rolling Screws (DIN 7500M Thread Rolling Screw Meaning the thread rolling process of screws involves deforming metal stock through the use of dies to create external threads along the surface. thread rolling screws are fasteners that create their own threads by displacing the material instead of removing it. 3.9k views 3 years ago #stemeducation #fasteners. thread rolling is commonly used in the production of screws,. Thread Rolling Screw Meaning.

From www.clecofasteners.com

Cleco Industrial Fasteners Specifications THREAD ROLLING SCREWS Thread Rolling Screw Meaning thread rolling is a straightforward process that begins with cutting a metal bar to length and forging it to create the bolt or screw. threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post. instead of removing material to create threads, thread rolling redistributes. Thread Rolling Screw Meaning.